No products

FAQ

- How the Balanced armature driver works

- How to choose a right helmet size

- Fiberglass or carbon fiber?

- How to choose a right microphone

- What are the dual-coil speakers

- How the active noise reduction works

- How to choose a right plug type

- How to NC-BT/ANR module works

- Headsets compatibility

- Which Aviation Headsets to Choose?

Viewed products

-

NC-900 programming...

This software allows programming of...

-

Classic aviation headset

Model NC-200MKII is for people who...

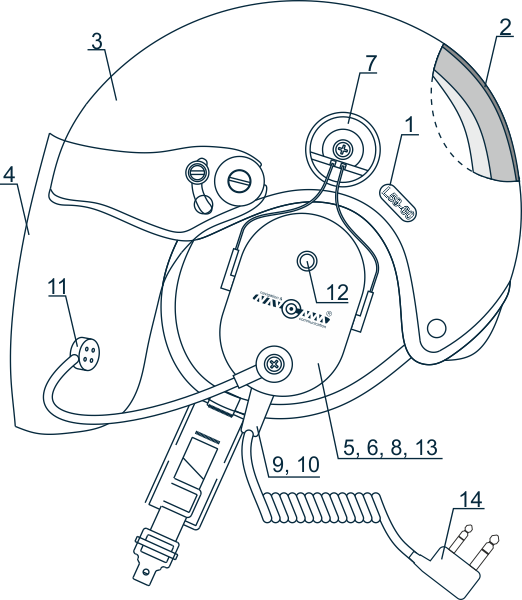

How to step by step complete a PPG helmet

1. Helmet size

The helmets offered by us are available in 6 basic sizes from XS to XXL . A detailed description of the selection of the appropriate shell size is described in the bulletin"How to choose a right helmet size"

2. Shell type

For the production of shells we use two types of fibers - carbon and glass. The basic differences between these two materials are described in the brochure "Fiberglass or carbon fiber"

3. Shell's color

Shells made of carbon fiber are painted with clear lacquer. In case of fiberglass construction, the shell is coated with covered lacquer - mostly white, black, or silver.

4. Visor

The PPG helmet can be optionally equipped with a face-lift visor. There are two types of visors - transparent and dimmed. The visors is fixed to the shell using a set of screws and can be removed or replaced at any time. The visor is made of polycarbonate (material used to produce windows in passenger planes), hardened on one side of the 1.8mm thick glass.

5. Communication

The essential element of a helmet for a powered paragliding is the headset . It has two basic functions - it protects your hearing from the noise generated by the motor and provides radio communication. The following steps describe the components of the kit.

6. Cups shape

We offer two cup shapes. The NC-100 type is more angular and suitable for gaskets (gel or foam). Its mounting to the helmet is done exclusively with Peltor hinged handles. Type NC-300 has rounded profile shells. For this profile both hinged and rigid mounts are available. The NC-300 profile has an additional flange for overlays (gel and foam). It also allows the use of cotton overlays.

7. Cups mounting

Peltors holders is a popular industry standard for fixing hearing protectors to the helmet. It consists of a plastic mechanism that allows you to change the position of the headphones in the front-back (smooth) and to and from the head (stepped). The combination of shells with the jaw mechanism provides a spring-tipped wire that allows you to adjust the proper headband attachment profile. The jaw mount is perfect for recreational flying. On high-performance flights, where there are higher speeds and overloads, rigid handles are the better option. In this case, it is not possible to tilt the headphones sideways to the side, however, the steel spring tape fixed to the helmet rigidly with a single screw provides a much better clamping of the cups to the head.

8. Cups color

Depending on the cups profile, different colors are available

9. The wire-cup connection

As standard, the headsets have a single, fixed multi wire cord that ends with a plug plugged into a particular radio model. When we planning for communication use different types of radio with a different sockets, the solution is a replacement cable connected to a multi-pin connector. The multi-pin connector is also a helper solution during ground preparation we can quickly disconnect it from the radio installation.

10. Additional mini-jack socket

This is one of the elements that extend the basic capabilities of helmet headsets. A single 3.5mm jack mounted at the bottom of the cup (without the microphone bracket) allows you to plug an external push-to-talk (PTT) button or connect an additional audio source to the headset (eg. Vario, GPS, smartphone ). This second feature requires replacing the speaker inserts on a dual coil.

11. Microphone type

Depending on the operating area of the set, different types of microphones are offered. A detailed description of this issue is in the bulletin"How to choose a right microphone"

12. PTT button

PTT is a feature that is offering by the transceivers which work in the semiduplex (reception and broadcasting can not take place simultaneously). Most radio stations in the semiduplex allow you to output the PTT button to the outside of the radio, so that you can place it on one of the headphone's cups. By default, it is mounted on the right cup of the headset. If for some reason should be located elsewhere please let us know about it.

13. Noise reduction

There are two solutions: passive reduction, realized by only sound absorbing materials and passive with additional active reduction , enriched with additional electronic circuitry to increase noise reduction. How does the process of active noise reduction occur? You can find out from the bulletin "How the active noise reduction works"

14. The plug type

The radio communication market offers very many types of connectors. Differences may arise both from the field of application (eg aviation) and the manufacturer's brand. Fortunately, there is a trend toward unification of the design in this area, so that with a dozen types of plugs we are able to ensure compatibility with most radio communications equipment used in aerial sports. Detailed instruction on the choice of connector type includes a bulletin "How to choose a right plug type"